GUIDE – Cavitating outboard motor: causes and solutions

Sailing peacefully, feeling the sea breeze and, suddenly, an abnormal noise interrupts this idyllic moment. Who has never been confronted with the inconvenience of a cavitating boat engine ? This disturbance, often overlooked, can be costly if not treated in time. The art of sailing is not just about mastering the currents and tides, but also about understanding and maintaining your boat. When the time comes to face a cavitation problem, do you necessarily have to go to a professional or are there methods at hand to remedy this problem? In this article, we explain everything about the phenomenon of cavitation, focusing on the main causes and the solutions that are most suitable for your situation. This guide is written specifically for boat owners facing a problem of cavitating outboard motor. So ready to embark on this mechanical adventure?

What are the symptoms of a cavitating outboard motor?

Before diving into the solutions, it is crucial to properly identify the signs that your boat is exhibiting. If you observe erosion and/or wear marks on the tips of your propeller blades, this article is definitely for you.

On the other hand, if you notice a loss of grip of the propeller as if it were emerging from the water (or sucking in air) during sharp turns and/or during high speed in a straight line... then you do not you don't have a cavitation problem but a ventilation problem. We advise you to read our article on outboard motors that ventilate. It will give you all the solutions to solve this problem.

Does your outboard motor have a "ventilation" or "cavitation" problem?

When an outboard motor loses its water intake and begins to blow air, it is said to be "venting". However, it is common to hear people claim, incorrectly, that the engine “cavitates”. In addition, the designation "anti-ventilation plate" is frequently substituted by " anti-cavitation plate“. This confusion is widespread in maritime parlance. Despite this common inversion of terms, it is crucial to distinguish between these two phenomena. Indeed, approaches to solving cavitating or ventilating outboard motor problems differ significantly.

Better understand the phenomenon of cavitation on a boat engine

The origins of the cavitation problem on a boat engine:

Cavitation is a complex phenomenon that occurs especially during high-speed navigation. At this time, the engine exerts increased pressure on the propeller, which increases the risk of disturbances in the flow of water around the blades. These disturbances are key factors in the appearance of cavitation. They can be exacerbated by a hull that is not perfectly clean, the incorrect installation of a transducer or the presence of irregularities on the hull. Once the disturbance of the water flow is created, the movement of the propeller will induce a significant reduction in the pressure of the surrounding water. This depression has the effect of transforming some of the water molecules into gas, resulting in the creation of microbubbles around the propeller. These microbubbles, initially formed by the gas contained in the water molecules, find themselves subjected to high pressure due to the continuous movement of the propeller. Under this constraint, they burst, thus triggering a problem of cavitating outboard motor.

Cavitation: what impact does this phenomenon have on your outboard motor?

When microbubbles created by cavitation burst, they generate shock waves. These waves can alter the integrity of the blades, compromising the longevity and efficiency of the propeller. It is common to observe distinctive erosion marks on the convex face of aluminum blades, evidence of a cavitation problem. Although stainless steel propellers are more robust, they are not completely immune to this scourge. These micro-eruptions gradually degrade the metal, and over time, signs of wear appear, particularly on the tips of the blades.

Understand the phenomenon of ventilation on a boat engine

The origins of the ventilation problem on a boat engine:

A ventilating outboard motor kicks in when the propeller starts sucking in air. This situation can occur during a tight turn, or even when sailing in a straight line at high speed, particularly if the engine is positioned too high on the transom or if it is too inclined (poor trim adjustment ).

Ventilation: what impact on the steering of your boat?

Designed to operate submerged, the propeller loses its effectiveness as soon as it begins to suck in air. As a result, the propeller's grip on the water decreases, causing the pilot to lose power and control. Without the resistance of the water, the revving of the engine is almost instantaneous, causing it to overspeed. This phenomenon can lead to overheating of the motor. In order to remedy this situation, the navigator is often forced to reduce the speed to allow the propeller to regain its optimal immersion.

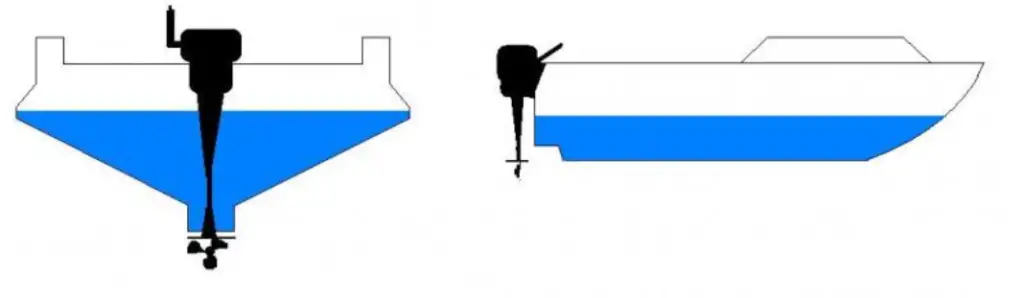

The anti-ventilation plate: an existing solution on all outboard motors

Above the propeller is a specific plate intended to prevent problems with outboard motors that ventilate: this is the anti-ventilation plate. It is often mistakenly called anti-cavitation plate. For it to be effective, especially when the boat is in the lift-off phase, this plate must be at the same level as the surface of the water. So if you have ventilation problems, it is very often due to this plate which is poorly adjusted.

For more information on the correct adjustment of the anti-ventilation plate, you can read our article: Causes and solutions for an outboard motor that vents.

The main causes of a cavitating outboard motor

After determining that the problem with your outboard motor is indeed due to cavitation (and not ventilation), it is essential to address this problem. Ignoring this situation is not recommended. Indeed, even if this phenomenon may seem trivial at first sight, its consequences on the engine and the performance of the boat can be detrimental:

- Propeller damage : One of the most visible consequences of a cavitating outboard motor is the progressive degradation of the propeller. Eventually, this can lead to erosion and even structural damage.

- Performance losses : An outboard motor that cavitates becomes less efficient. The propeller, being partially surrounded by air bubbles rather than water, has less grip. This results in a decrease in thrust, a reduction in speed and an increase in fuel consumption.

- Excessive noise and vibration : A cavitating outboard motor generates a characteristic noise, often described as a rumbling or crackling sound. Moreover, a deformed propeller will emit vibrations which can damage your outboard motor in the long run.

It is therefore crucial to understand cavitation, identify its causes and implement the appropriate solutions to protect the integrity of your outboard motor and guarantee safe navigation.

Finding the cause of a cavitating outboard motor

To effectively troubleshoot a cavitating outboard motor problem, it is essential to understand its causes. Let's dissect together the main reasons why an outboard motor can cavitate:

- Dirty hull : Dirt, algae, or other encrustations on the hull can disrupt the flow of water to the propeller. This disturbed water flow can create areas of low pressure, favoring the appearance of bubbles, the main player in cavitation.

- Improper probe installation : An incorrectly installed or positioned transducer can create turbulence in the water feeding the propeller. These disturbances can, in turn, encourage the formation of bubbles and therefore cavitation.

- Presence of irregularities on the hull : Just like a dirty hull, irregularities or deformations on the hull can disrupt the flow of water, making the outboard motor more susceptible to cavitating.

- Inappropriate propeller : Using a propeller that is not suitable for the size of the boat, the type of engine or the style of boating can lead to poor water circulation around the propeller. This poor circulation can create vacuum zones, promoting cavitation.

- Damaged propeller : A damaged propeller, with eroded, deformed or cracked blades, cannot operate at its optimal efficiency. Blade deformation can cause uneven distribution of water flow, creating the ideal conditions for cavitation.

- Engine boost : Pushing an outboard motor to higher rpms than it was designed for can also promote cavitation. A supercharged engine works in conditions for which it has not been optimized, which can disrupt the normal operation of the propeller.

Our proven solutions to a cavitating outboard motor problem

Every cause of a cavitating outboard motor has its solution. Let's explore together the corrective measures to be taken according to the causes mentioned.

How do I clean a dirty hull to prevent my outboard motor from cavitating?

A dirty hull is more than just an aesthetic inconvenience; it can become a major cause of cavitation for your outboard motor. Luckily, with the right tools and techniques, cleaning your hull can be a simple task (and an effective solution). Here's how to do it step by step:

- Prep time : Put the boat on a trailer or in a space where you can easily access the hull.

- Initial rinse : Begin by rinsing the hull with fresh water to remove salt, algae and surface debris.

- Soaping : Use a mild detergent specific for boats and a soft-bristled brush to gently scrub the shell. Work in sections, from top to bottom, avoiding letting the soap dry.

- Treating stubborn stains : If your hull has white spots of mineral deposits, consider using white vinegar.

- Organic stains : Algae or mold stains may require special treatment. Use a cleaner designed to remove these messes.

- Anti-fouling treatment : After cleaning the shell, consider applying antifouling paint. These paints are designed to repel marine organisms, preventing their growth on the hull and therefore reducing the risk of cavitation.

- Regular maintenance : To prevent the formation of dirt and incrustations, rinse the hull regularly with fresh water after each ride. Also, schedule deep cleanings at regular intervals based on how often you use your boat.

A well-maintained hull is essential to ensure smooth water flow to the propeller and thus prevent cavitating outboard motor problems.

Captain's advice :

Also remember to clean the base of your outboard motor well to ensure a smooth flow of water to the propeller.

How to replace a damaged propeller?

Regularly inspect your propeller for any signs of damage – especially on the blade tips. At the slightest anomaly, replace it or have it repaired by a professional. A propeller in good condition is essential to prevent your outboard motor from cavitating.

To replace a propeller, simply follow these steps:

- securing : Make sure the engine is off and the ignition key is removed. Position the motor so that the propeller is easily accessible.

- Propeller removal : Remove the pin and retaining nut using a suitable wrench. Once the nut is removed, you should be able to remove the propeller from the hub. If it's stuck, give it a light tug to loosen it.

- Prep time : Clean the motor shaft to remove any residue or debris and coat it with specialized marine grease.

- Positioning : Place the new propeller on the shaft, making sure it fits snugly on the hub. Replace the nut and tighten it. Make sure it is snug, but do not over force or damage the shaft or propeller.

- Placement of the pin : Secure the propeller by fitting a new pin. You will have to bend it on either side of the nut.

A properly positioned propeller in good condition is essential to keep your outboard motor running smoothly and to prevent cavitation.

Captain's advice :

You will find used propellers on online sales sites such as ebay.

Inappropriate propeller: A major source of cavitation and the keys to selecting it

A crucial element to ensure the optimal functioning of an outboard motor is undoubtedly the propeller. The wrong propeller for your boat or outboard motor can not only reduce performance, but also promote cavitation. Understanding the characteristics of a propeller and knowing how to choose the right one is therefore essential.

How to choose the right propeller for your boat engine?

It is crucial to ensure that the propeller matches the engine power, the size of the boat and the desired speed.

- Consult your outboard motor manufacturer : Manufacturers often provide propeller recommendations for each engine model. It's a great starting point.

- Diameter : This is the total distance that the propeller covers when it turns. A large diameter propeller can provide more thrust, but it requires a more powerful boat motor.

- Dog : This is the theoretical progression of the propeller in one turn. A high-pitch propeller increases speed, while a low-pitch propeller increases pulling power. However, a propeller pitch that is too short increases the engine speed while decreasing the maximum speed. Conversely, too long a propeller pitch puts excessive stress on the engine, increasing fuel consumption and accelerating wear.

- material : The propellers can be made of aluminum, stainless steel or composite. Stainless steel is strong and durable, but more expensive. Aluminum is less expensive, but may deteriorate more quickly.

- Number of blades : Increasing the number of blades, for example from three to four, can reduce ventilation. The ideal number depends on the use: three blades to favor speed, four or five for more stable navigation (the more blades there are, the softer and more stable the thrust, but this can reduce the maximum speed).

Depending on everyone's preferences, we will refine the selection by emphasizing speed, acceleration when planing, or consumption. Every decision is the result of a compromise. Some manufacturers offer specialized propellers for each type of performance.

Captain's advice :

The correct propeller must allow the maximum rpm recommended by the manufacturer to be reached. If you are in doubt, do not hesitate to consult a propeller expert or a specialized mechanic for sound advice.

Engine supercharging: Solutions to counter cavitation

Overcharging an outboard motor can create excess power which, in turn, can lead to cavitation. This problem is frequently encountered when a boat engine is pushed beyond its recommended limits. Here are solutions to deal with this problem:

- Review your outboard motor specifications : Make sure you know the optimum RPM range for your engine. Each engine has specific recommendations, and it is essential to comply with them to avoid overcharging.

- Constant monitoring : Use a tachometer. This device will allow you to monitor the engine speed in real time. If you notice that the engine is regularly running at too high an RPM, this may indicate a boosting problem.

- Propeller optimization : If your engine is frequently overfed, consider adjusting the gear ratio to a propeller with a different pitch. This can help balance the power delivered by the engine, thus preventing excessive revs.

Cavitating outboard motor: when to consult a professional?

When faced with a cavitating outboard motor, it is recommended to call a professional when the cavitation is due to the following causes:

Incorrect installation of a probe:

Make sure the transducer does not interfere with the flow of water going to the propeller. If you suspect improper probe installation, check the manufacturer's manual first. It usually provides detailed instructions on the ideal location for the probe. If you have any doubts about the installation or if, despite the repositioning, the problem of the cavitating outboard motor persists, it is strongly recommended to consult a specialist.

Presence of irregularities on the hull:

A careful examination of the hull is essential. If you identify any dents, scratches or deformations, even minor ones, then they may be responsible for your problem. cavitating outboard motor. It is therefore wise to call in an expert to restore the surface.

Conclusion on cavitating outboard motors

Cavitation, through its sound and vibration manifestations, alerts us to a malfunction which, if not treated in time, can cause irreparable damage to your engine. Understanding the underlying causes is essential. Whether it's a dirty hull, an unsuitable propeller or engine overcharging, every problem has its solution. Some diagnoses and solutions can be tackled by the owner themselves with a little effort and research. However, the complexity of certain problems and their resolution require the intervention of a professional. Don't take unnecessary risks; If you are in doubt, consulting an expert is always the best option. Be sure to take care of your outboard motor to ensure peaceful and safe navigation.

Cavitating outboard motor FAQ: how to solve the problem?

Cavitation is a hydrodynamic phenomenon where bubbles (vapour pockets) form in the water around the propeller. When these bubbles implode, they can cause damage, creating problems for the cavitating outboard motor.

If you hear an abnormal noise, similar to a rumbling or gravel noise, this is often the first sign. Also, a loss of power or inefficiency when accelerating can be a sign of a cavitating outboard motor.

Several factors can contribute to cavitation: a damaged or inappropriate propeller, overpowering the engine, irregularities on the hull, or even incorrect installation of a probe. We discuss the most common causes and their solutions in our article

Prevention is the key. Regular inspection of your boat's propeller and bottom is essential. Also, make sure the propeller is the right fit for your outboard motor, your boat, and your boating style. If you have any doubts, do not hesitate to consult a professional.

First, identify the underlying cause. For example, if the problem is a damaged propeller, consider replacing it. For more complex issues like irregularities on the hull, it might be a good idea to consult an expert.

Learn more about outboard motors:

GUIDE: Fixing an Outboard Motor That Shakes at Idle