GUIDE Outboard motor that vents: causes and solutions

Sailing with serenity is the dream of every sailor. But imagine that dream being suddenly interrupted by a boat engine that ventilates. Suddenly, your boat seems to be breathing hard, struggling against waves, currents and wind. A ventilating outboard motor isn't just a noise disturbance or a drop in performance. It is an alert, signaling that an element, somewhere, is not in its optimal place. Whether it's poor balance, improper engine position or improperly adjusted trim, every detail counts. Fortunately, for every problem, there is a solution. So, are you ready to solve your ventilation problem? In this article, we will methodically examine the common causes of a outboard motor that ventilates and present the most effective solutions to remedy them. The ultimate goal is to ensure smooth and secure navigation in all circumstances for you and your passengers.

What are the symptoms of an outboard motor that is venting?

Before diving into the solutions, it is crucial to properly identify the signs that your boat is exhibiting. If you find yourself in one of the following situations, this article is definitely for you:

- You notice a loss of propeller grip during sharp turns, as if it were emerging from the water.

- When cruising at high speeds in a straight line, your engine seems to be sucking in air, suddenly accelerating unrestrainedly.

Does your outboard motor have a "ventilation" or "cavitation" problem?

When an outboard motor loses its water intake and begins to blow air, it is said to be "venting". However, it is common to hear people claim, incorrectly, that the engine “cavitates”. In addition, the designation anti-ventilation plate is frequently substituted by “anti-cavitation plate”. This is a common confusion in maritime parlance. Despite this common inversion of terms, it is crucial to distinguish between these two phenomena. Indeed, the approaches to solving cavitation and ventilation problems differ significantly.

Understand the phenomenon of ventilation on a boat engine

The origins of the ventilation problem on a boat engine:

Un outboard motor that ventilates occurs when the propeller begins to suck in air. This situation can occur during a tight turn, or even when sailing in a straight line at high speed, particularly if the engine is positioned too high on the transom or if it is too inclined (poor trim adjustment ).

Ventilation: what impact on the steering of your boat?

Designed to operate submerged, the propeller loses its effectiveness as soon as it begins to suck in air. As a result, the propeller's grip on the water decreases, causing the pilot to lose power and control. Without the resistance of the water, the revving of the engine is almost instantaneous, causing it to overspeed. This phenomenon can induce engine overheating. In order to remedy this situation, the navigator is often forced to reduce the speed to allow the propeller to regain its optimal immersion.

The anti-ventilation plate: an existing solution on all outboard motors

Above the propeller there is a specific plate intended to prevent problems with outboard motor that ventilates : this is the anti-ventilation plate. It is often mistakenly called anti-cavitation plate. For it to be effective, especially when the boat is in the lift-off phase, this plate must be at the same level as the surface of the water. So if you have ventilation problems, it is very often due to this plate which is poorly adjusted.

Better understand the phenomenon of cavitation on a boat engine

The origins of the cavitation problem on a boat engine:

Cavitation is a complex phenomenon that occurs especially during high-speed navigation. At this time, the engine exerts increased pressure on the propeller, which increases the risk of disturbances in the flow of water around the blades. These disturbances are key factors in the appearance of cavitation. They can be exacerbated by a hull that is not perfectly clean, the incorrect installation of a transducer or the presence of irregularities on the hull. Once the disturbance of the water flow is created, the movement of the propeller will induce a significant reduction in the pressure of the surrounding water. This depression has the effect of transforming some of the water molecules into gas, resulting in the creation of microbubbles around the propeller. These microbubbles, initially formed by the gas contained in the water molecules, find themselves subjected to high pressure due to the continuous movement of the propeller. Under this constraint, they burst, thus triggering the observed cavitation phenomenon.

Cavitation: what impact does this phenomenon have on your outboard motor?

When microbubbles created by cavitation burst, they generate shock waves. These waves can alter the integrity of the blades, compromising the longevity and efficiency of the propeller. It is common to observe distinctive erosion marks on the convex face of aluminum blades, evidence of a cavitation problem. Although stainless steel propellers are more robust, they are not completely immune to this scourge. These micro-eruptions gradually degrade the metal, and over time, signs of wear appear, particularly on the tips of the blades.

What are the solutions to counter the cavitation problem?

To limit cavitation, various interventions can be considered. Make sure the hull is clean and free of dirt. A good fairing of the submerged parts is also crucial. It is also advisable to check the integrity of the blades of the propeller and to clean the foot of the base. If the problem persists, it may be a good idea to reposition the sonar transducer. Finally, in some cases, replacing the propeller may be necessary. For a more in-depth analysis, do not hesitate to consult our detailed article on the subject: “ Cavitating outboard motor: causes and solutions"

Our proven solutions for an outboard motor that ventilates

After determining that the problem with a drafty engine is undoubtedly related to ventilation (rather than cavitation), it is essential to address this problem. Ignoring this situation is not recommended, as side effects could be harmful:

- Decline in performance : The engine loses power significantly, thus affecting the capabilities of your boat.

- Loss of control : an outboard motor that vents can reduce the maneuverability of your watercraft, posing safety concerns.

- Unstable engine speed : The motor may experience sudden accelerations, showing signs of instability.

- Risk of overheating : Without intervention, the engine can reach critical temperatures, which can cause irreversible damage.

Faced with these problems, adapted solutions are necessary to guarantee the safety and longevity of your outboard motor.

Find the cause of an outboard motor that vents

The correction of the "ventilation" phenomenon is essentially based on readjusting the height of the motor so that the propeller remains constantly submerged. However, the challenge is not only in how to lower the motor, but more importantly in understanding why it is in a too high position. Understanding the origin of this imbalance is essential to provide the appropriate solution.

Three incorrect settings can be the cause of an outboard motor positioned too high:

- Boat imbalance : An uneven weight distribution on the boat can cause this inconvenience. It will therefore be necessary to review the distribution of loads on board to lighten the bow.

- Ill-adjusted trim : Improper trim settings can be the cause of a ventilating outboard motor. In this case, a more precise adjustment of the trim is necessary.

- Positioning of the engine too high on the transom : If the outboard motor is mounted too high, consideration should be given to reinstalling it at a more suitable height.

Each of these settings will be reviewed in detail to provide you with targeted recommendations to prevent your outboard motor from venting in the future.

Readjustment of weight on board

The balance of your boat is crucial when you take to the open sea, especially if your hull is light and responsive to changes in weight. Have you noticed that the ventilation problem occurs especially when you are in the company of other passengers? It is essential to consider whether the boat is overloaded, especially at the bow.

It is not uncommon to observe on bodies of water, particularly on small boats, several passengers on board, including one positioned at the front, accentuating the lifting of the stern. This configuration may be the cause of a outboard motor that ventilates.

To remedy this problem, it is recommended to rebalance the loads by shifting more weight to the rear, especially when the boat accommodates many passengers.

Optimal trim setting to prevent ventilation of your outboard motor

Understanding trim:

Trim, often referred to as power trim, is an electrical mechanism that allows the outboard motor to be tilted either up or down through a button usually located on the gear lever. It is actually a hydraulic cylinder that changes the thrust angle of the propeller, thus impacting the position of the boat on the water. In simple terms:

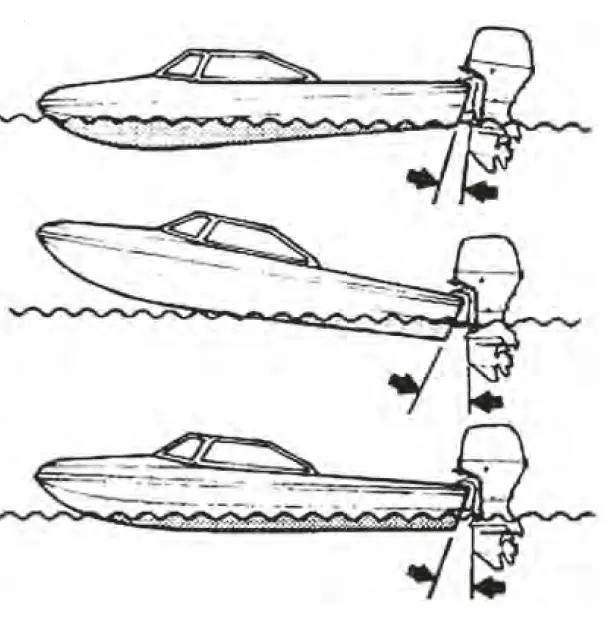

- When the trim is negative, the lower part of the motor moves closer to the boat, plunging the bow into the water. (the top image on the chart)

- When trim is positive, this part moves away from the boat, causing the bow to rise. (the middle image on the chart)

- When the trim is neutral, the lower part of the motor is neither too close nor too far from the boat. Therefore the bow is neither raised nor dipping. (the bottom image on the chart)

How to adjust the trim to prevent your boat engine from winding up?

The short answer:

To no longer face a outboard motor that ventilates, shift the trim to a negative position during fast turns or hard acceleration.

The detailed version:

Sailors use trim to allow the boat to rise quickly out of the water. This is a phenomenon known as lift-off. When this happens, the boat literally glides on the water (hydroplaning), reducing friction on the hull and therefore fuel consumption, while gaining speed and comfort. To achieve effective lift-off, the steps are simple, but despite everything, many pilots find themselves in a ventilation situation. Follow these steps to learn how to plane without venting your outboard motor:

- Start with the trim in the negative (maximum) position to increase the initial speed of the boat.

- In calm sea conditions, as speed increases, the boat will begin to lift out of the water.

- Once hydroplaning (not forward), slowly adjust the trim to a positive position, reducing friction with the water and increasing speed.

- When properly adjusted, trim can increase engine speed by 200 to 400 rpm, which translates to a 2 to 3 knot speed improvement.

- Stop increasing trim when the increase in engine speed no longer translates into an increase in speed. This indicates that you have reached the optimal trim limit.

- If you continue to increase the trim, the propeller may vent, making the boat's handling unstable.

In short, once the planing is reached, the trim should be adjusted so as to obtain the maximum speed without excessively lifting the propeller out of the water.

Captain's advice:

- In the event of a swell coming from the front, opt for a slightly negative trim to avoid sudden jumps.

- Faced with a swell coming from astern, a slightly positive trim will prevent the boat from plunging suddenly into the waves.

Adjust the height of the outboard motor to prevent it from venting

Indicators of a misplaced outboard motor:

When weight adjustment or trim adjustment do not solve the outboard motor ventilation problems, the motor may be mounted too high. A clear indicator of this problem is when it becomes difficult to set the trim in the positive position after taking off plane or making a sharp turn without the engine starting to vent. A difference of only 1 to 2 centimeters in the position of the outboard motor can be the cause.

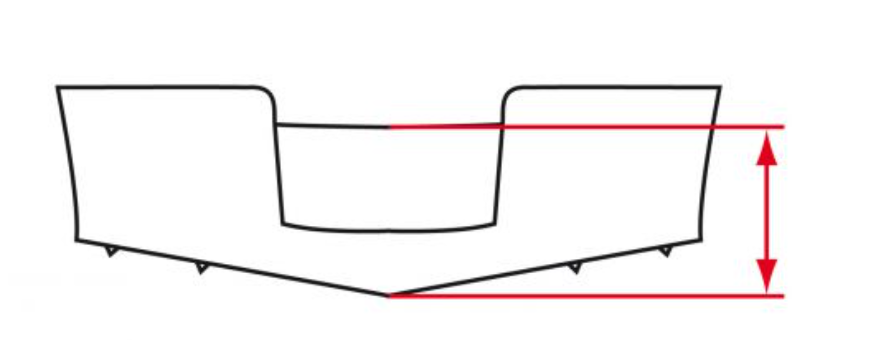

The key: a well-positioned anti-ventilation plate

The anti-ventilation plate is crucial for the proper functioning of your outboard motor. Its main role is to prevent the propeller from stirring air, thus avoiding a reduction in speed. For it to be effective, this plate must be correctly aligned. When the boat is on plane, it should be on the surface of the water.

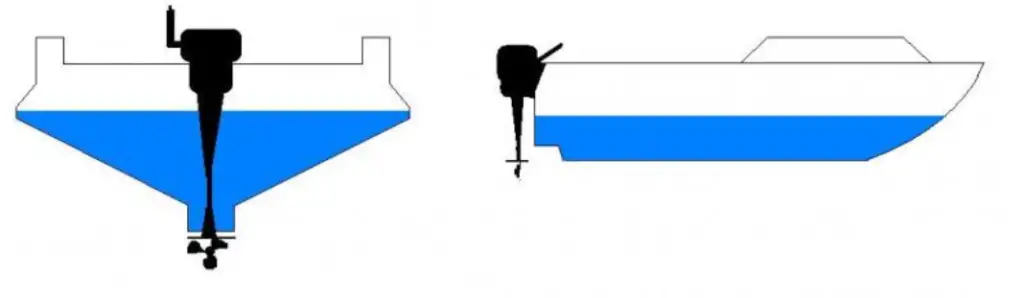

Instruction for correctly installing an outboard motor and its anti-ventilation plate

The standard procedure for installing an outboard motor is to align the anti-ventilation plate with the lowest part of the hull. To ensure precise alignment, a ruler placed under the hull can be used, ensuring that the plate is in a straight line with it and not tilted. For sailboats, the anti-ventilation plate should be flush with the flat bottom of the hull rather than the keel.

Note: Your manual may refer to the anti-ventilation plate as the "anti-cavitation plate". It means the same thing but it is a language error.

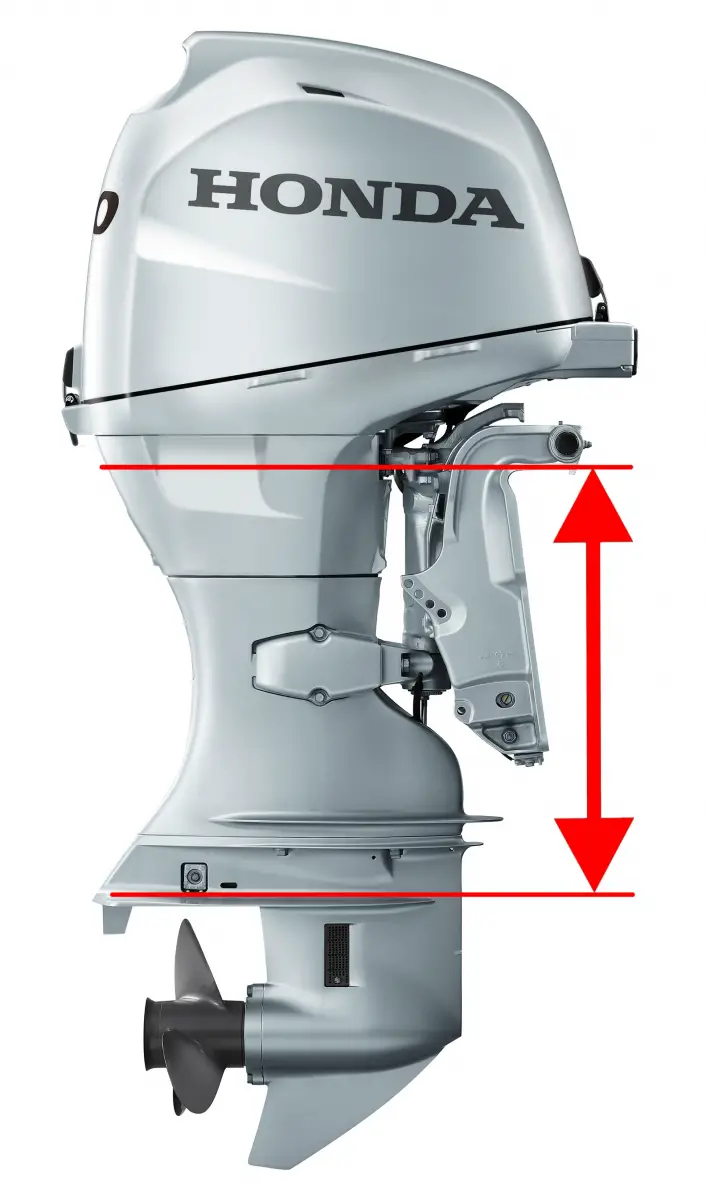

The importance of shaft length:

The length of the shaft is essential to ensure that the outboard motor correctly accommodates the height of the transom. The distance between the top of your transom and the lowest point of your hull (right graph) should be as close as possible to the distance between the outboard motor mounting and the anti-ventilation plate (graph from the left).

For more information, you can read our article: How to choose the right shaft length for my boat engine? Once the appropriate length has been chosen, adjustments can still be made by mounting the motor higher or lower on the transom.

CAUTION: It may be tempting to buy a motor with a long shaft to be sure that you do not have a problem of outboard motor that ventilates. But a shaft that is too long could cause problems like excessive drag or even long-term transom damage. In this case, it is recommended to use shims to adjust the height.

Solution for too high transom:

If the height of an outboard motor is not suitable for your boat (even with a long shaft), modifications may be necessary. One solution is to cut out a portion of the transom so that the anti-ventilation plate is perfectly aligned with the bottom of the hull.

The photo below shows a perfectly installed anti-ventilation plate:

Outboard motor that ventilates: when to consult a professional?

Sometimes, despite your best efforts and adjustments, you may not be able to fully resolve issues with a outboard motor that ventilates. In such scenarios, consulting a professional becomes imperative. Do not take unnecessary risks with your safety or that of your loved ones.

Conclusion on outboard motors that ventilate

Understand and remedy the problems of a outboard motor that ventilates can be a real challenge. However, by taking a methodical approach, examining each potential cause and applying the appropriate solutions, you can significantly increase your chances of fixing this problem. And remember, when all else fails, consulting a professional is not a sign of failure, but rather a proactive step to ensure your engine's longevity and peak performance. Navigate safely and always pay attention to any signs your engine may be giving you.

FAQ on outboard motors that vent: what to do?

A winding outboard motor occurs when a propeller spins so quickly that it begins to draw air from the surface, rather than water, causing a loss of propulsion. This is a common situation when the boat engine vents, especially with outboard motors.

Several factors may contribute to this phenomenon. This may be due to poor weight distribution on board, incorrectly adjusted trim or too high a position of the engine in relation to the water level.

A telltale sign is the ability to trim positively once off the plane. If you can't trim in positive or if you vent while cornering, your engine could be too high. Sometimes a difference of just 1 or 2 cm can cause problems.

The anti-ventilation plate ensures a strong and continuous flow of water over the propeller, preventing air from being sucked in. Its precise positioning is crucial to prevent the phenomenon of ventilation, in particular during planing

In situations like this, it would be wise to consult a professional in the field. Although common solutions can often solve the problem, more complex cases require the expertise of a specialist.

Learn more about outboard motors:

GUIDE: Fixing an Outboard Motor That Shakes at Idle